|

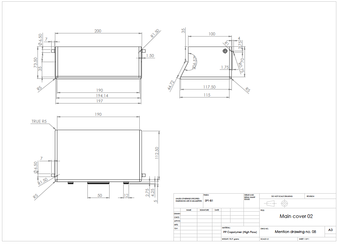

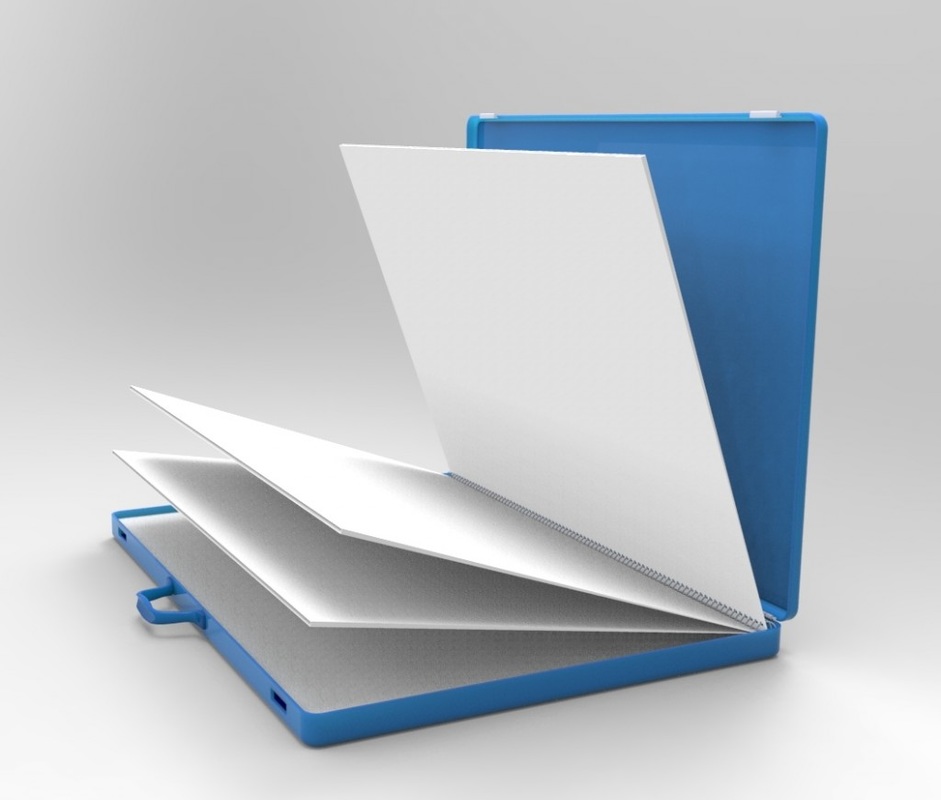

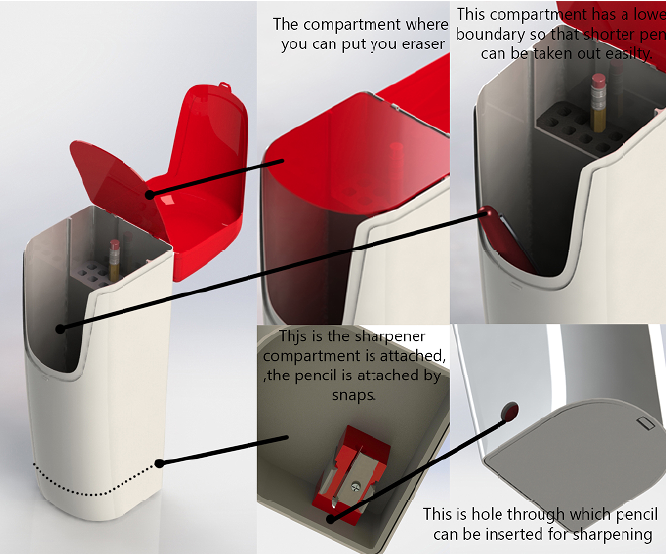

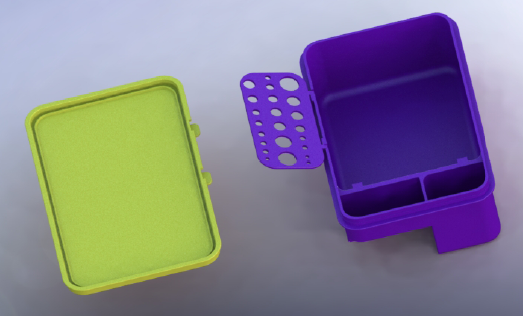

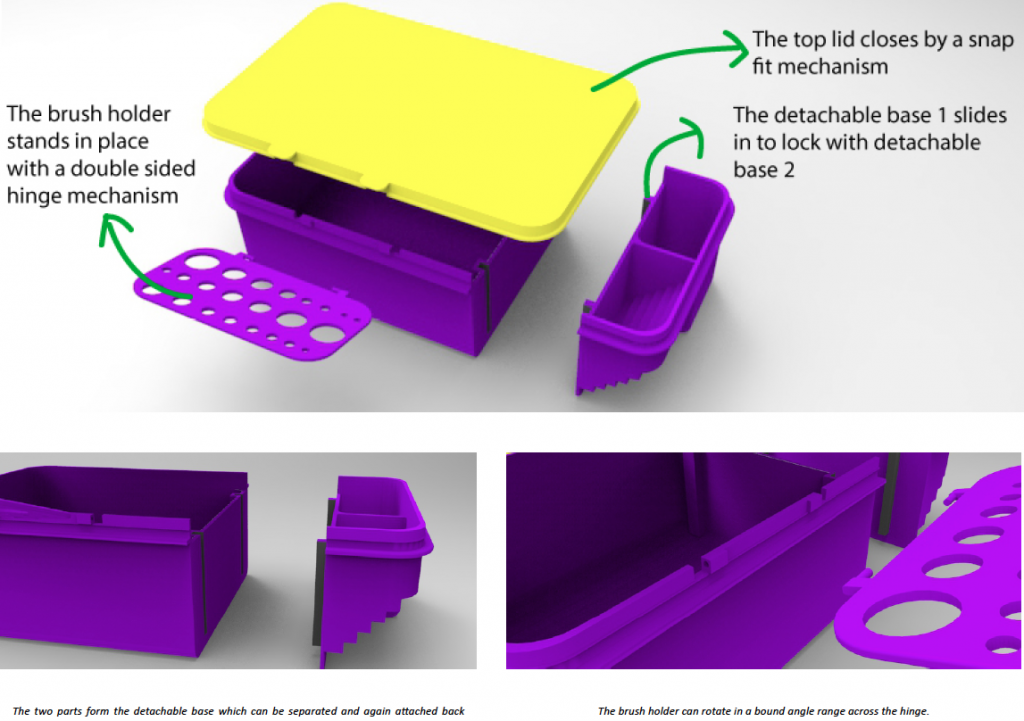

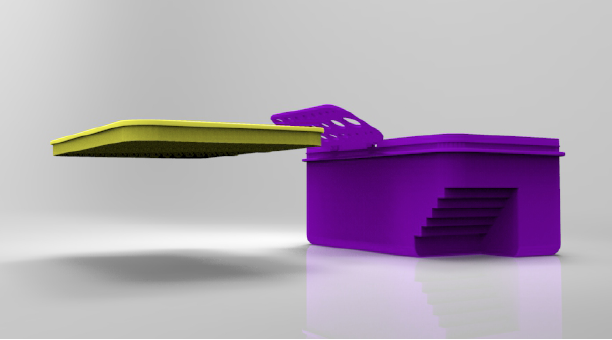

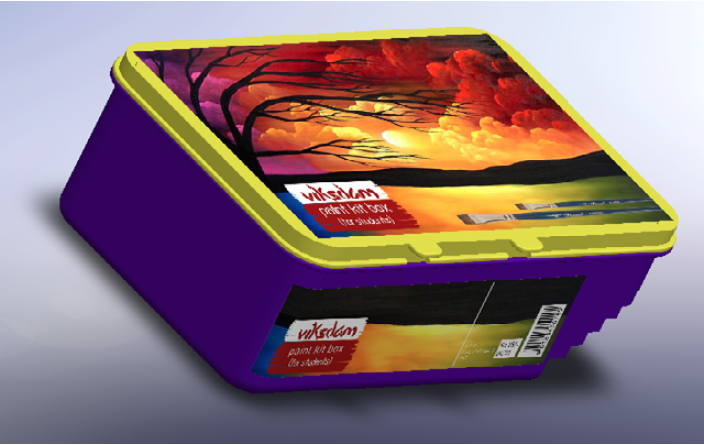

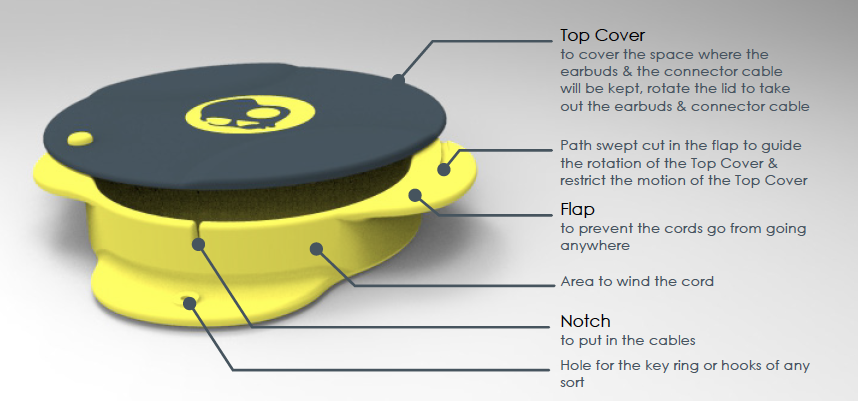

The 2nd year (4th semester) Bachelor of Design students have a theoretical course called: Plastics and Composites. The course content as per curriculum is as follows: Introduction to plastics and their applications. Classification of Plastics: thermo-setting and thermo-forming. Identifications of plastic: physical tests and chemical tests. Processing of plastics: Injection molding, Compression molding, blow moulding, vacuum forming, roto-molding, extrusion, pultrusion, transfer molding, SMC etc. Introduction to composites and their applications. Classification of composites: Fibre Reinforced Plastics (FRP), other types of FRPs. Designing in plastics and composites. The first year that I took the course, I tried to give theory, and then some product examples, videos and an industry visit. Due to very high theoretical nature of the course, the students seamed very uninterested right from day 1 of the class. Also the students didn’t see a clear reason regarding why they should take a course of this type as a compulsory course. Also Guwahati being not a place where all plastic processes can be shown to the students through industry visits, the theoretical concepts seemed more difficult to grasp for the students. Hence the next year a new approach was taken. Learning through Discovery On day one of the course, a pile of 100 different types of everyday use plastic products were brought in the class. The students were divided into groups of 5. Each group was given a plastic pen and asked to carefully note down the number of different plastic parts that it had, has w the parts were joined to each other and what type of property was used in different parts of the pen and why. Once they were done with their pen, they would exchange it with another group. At the end of the session, each student could identify different plastic joineries, that plastic is not one material but a group of different types of materials with varied properties and we select them depending on the intended use. Thus the reason for doing the course was grasped intuitively. Next the students were asked to imagine how each of the component could have been manufactured. Interestingly the students could imagine injection moulding, blow moulding, insert moulding, etc. without even having any theoretical knowledge of these processes. Next the same procedure was repeated for a set of 5 different types of plastic containers which differed from each other in the way they lock and unlock. The students intuitively identified and understood concepts of snaps, threads, live hinge and their construction without any theoretical inputs. Next they were given a set of plastic ladles and they could imagine the process of manufacturing and discovered the concept of parting line. Next a set of plastic cups were given and that helped them to further understand parting lines and undercuts. Following this process of Learning by Discovery, the students discovered almost all plastic processes and detailing in their very 1st class which was of 3 hours duration. Thereon making connections while presenting theory was much more effective. As a result of the 1st day of discovery, the students in this course could design very well detailed plastic containers as part of the course assignment. The containers designed were of much higher quality as compared to those designed by the previous batch of students. Some of the designs are presented below. Figure 5: An Oil Pastel carry case by Kohli Akkash Pavankumar and Harmeet Singh

0 Comments

Your comment will be posted after it is approved.

Leave a Reply. |

Archives

March 2023

Categories

All

Archives

March 2023

|

RSS Feed

RSS Feed