Internship and Research Associate Projects completed at SSi Lab

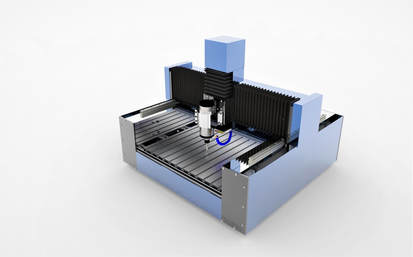

Modulus 1: Design of a Semi-Industrial Modular CNC machine

Faculty Mentor: Pankaj Upadhyay

Modulus 1 project started with the aim of implementing modularity in the design of a modern day gantry based industrial CNC machine. Implementation of a modular architecture in gantry based CNC machines will result in the economically cheaper expansion of the product family, increased product life, easier upgrade and lower manufacturing costs. During any part of the product life-cycle any significant changes to the functionality can also be achieved by changing only some selected components in the design. After completion of the detailed CAD, the modularity and product architecture was further analysed and optimized using Design Structure Matrices. The initial sketches for the Industrial design of CNC started with the vision to design a product that is robust, industrial, user-friendly and minimalist. After a significant number product sketches, a final design was selected and developed via CAD. The interfaces and access panels were designed considering the interactions between between the system and the operator, during various types of usage scenarios. Ayushman and Abhishek worked on the Engineering Design and Industrial Design of the product respectively under the guidance of Prof Pankaj Upadhyay at the Sustainability and Social Innovation Lab at the Department of Design IIT Guwahati. At the completion of the project, the detailed CAD design of the product, as well as manufacturing ready drawings were completed. The next phase of the project is being pursued further, wherein the team is developing the first prototype of the machine. The team is also working to develop a concept with better industrial design, packaging and branding for the product. |

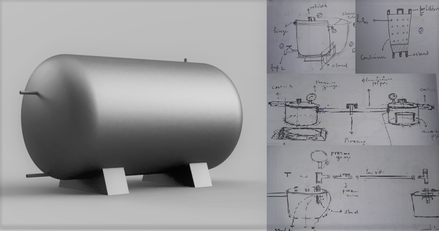

Design of Turmeric Steamer for Small Scale FarmsFaculty Mentors: Pankaj Upadhyay, Sharmistha Banerjee

India produces 90% of the turmeric consumed in the whole world, out of which only 0.5% is grown in North East Belt. Even when the soil and weather conditions are favorable for turmeric growth. The main reason of this small growth is lack of return to farmers even after high market demands that is because of the post processing steps involved in the taking raw turmeric to powder form. These post value addition processes are very labor intensive and expensive for the farmers, but they are the means of getting high returns and making turmeric a profitable cash crop. In this project, the post process of boiling of turmeric was taken for study, evaluation and intervention. Our major target audience were medium and small scale farmers of Assam who had a land holding of less than 2 acres. it was found that boiling of turmeric comes with a lot of problems such as reduction in curcumin content, energy requirement, degradation in quality. As a result, the project aimed to develop a solution for steaming the turmeric to achieve the desired results without the difficulties and problems associated with boiling. A final working frugal prototype was developed using pressure cookers as boilers and steam generators to find the efficacy of the solution. |